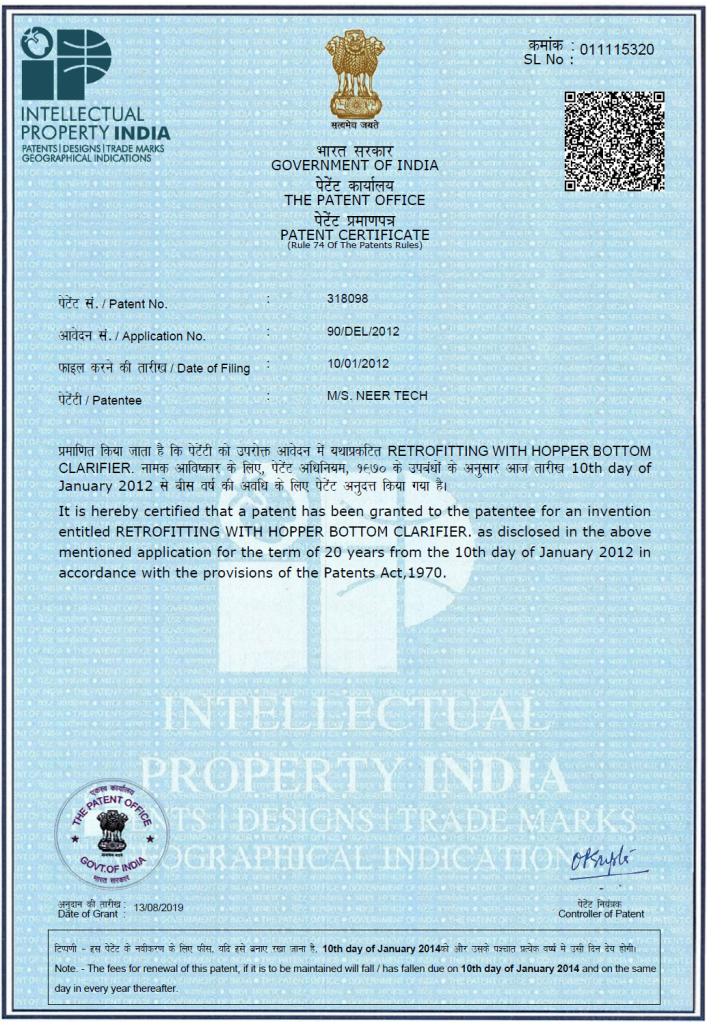

The Patent lies with us..

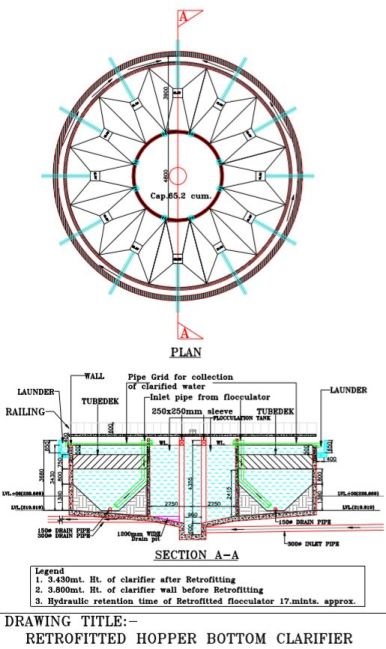

Our technology DOUBLES, in the least, output of treated water of the existing Conventional Water Treatment Plant. with controlled and optimum disposal of sludge from the Retrofitted Hopper Bottom Clarifier under different turbidity of raw water using Tube Settler System.

The technology majorly deals with upgrade of the existing Water Treatment Plant with Retrofitted Hopper Bottoms and Tube Settlers for Community Water Treatment plants not fitted with Tube Settler Media, and Siphon Filter arrangement. The concept envisages restructuring of existing Conventional Clarifier/Settling Tanks of WTP by modifying the shape of the tanks and changing the hydraulics to enable increase of the surface loading rate per unit area.

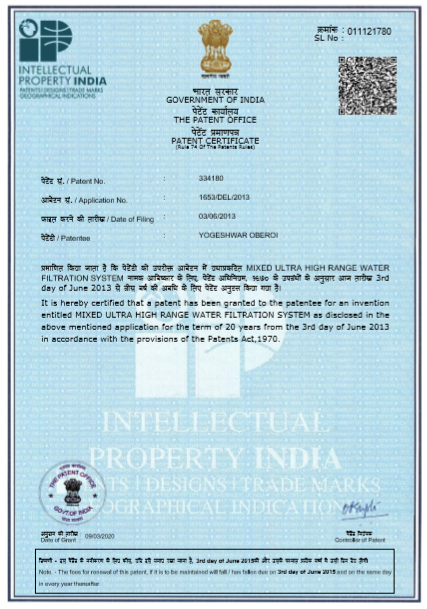

The Retrofitting of existing Clarifier and Filter with Hopper Bottoms and Siphon arrangement, respectively are patented Technologies under Intellectual Property Rights Act, India, vide patent nos. 318098 and 334180 according to the provisions of the Indian Patents Act, 1970.

In the case of old existing water treatment plants which are in densely populated urban areas there is always a situation where by the water supply is only for a few minutes. By retrofitting and Upgrade these plants can give double the quantity of water from the existing facilities. The materials used in invention consume only approximately 50% of the energy quotient while Retrofitting the plant when compared to setting up a new Water Treatment Plant. The investment is only 25% of the finances required for setting up new Plant while DOUBLING the treated water output. It is a sustainable technology for which the Govt. of India is pushing for adoption. With the savings of cement and steel, using this technology, it is environmentally friendly and need of the hour for adoption.

The Retrofitted Hopper Bottom Clarifier Will Produce in the least DOUBLE the amount of Clarified water without any major Civil and Mechanical costs required for the upgrade of existing conventional clarifier /settling tank.

Saving in civil structure cost as no new structure has to be constructed for doubling the capacity of existing plant.

Saving in land required for construction. Generally, in the existing treatment plant extra flash mixer can be accommodated.

No requirement of additional staff. This results in great saving of operational cost.

The laborious, time consuming and expensive process of land acquisition is dispensed with.

Less construction time required for start-up of Retrofitted Water Treatment Plant. No shut down in the supply of clarified water as settlement is continuous and supply is maintained. Existing tanks have to be emptied and then cleaned.

Minimum wastage of water during draining out of sludge.

Sludge is removed while the Retrofitted Clarifier is running.

Easy to operate and maintain as there is no mechanical equipment in the Clarifier Tank aside from inlet valve and sludge valve.

Smaller size of Clear Water reservoirs required as there is no shut down of filter plant.

Guaranteed to reduce S.S. to below 10 PPM.

Care has to be taken to avoid bottlenecks between enhanced reactor capacities and corresponding pipes and valves.

There can be requirement of equalization tank to suppress slow peaks and surges.

There is a requirement for continuous and skilful monitoring of consistency of sludge being wasted from hopper bottom.

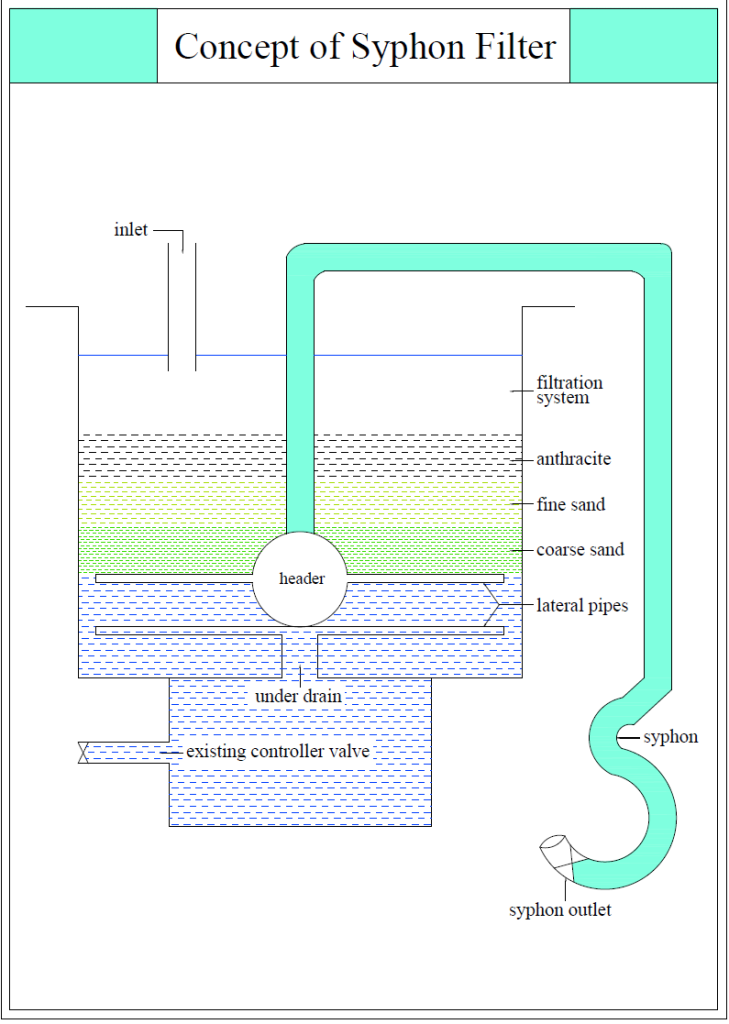

Siphon filter is an innovation used for the treatment of water for domestic use, using the Multi- Media filter. It consists of Dual Media Filter also referred to as Rapid Gravity Sand Filters with two horizontal layers, anthracite, and sand respectively as moving towards the bottom. Rapid Gravity Dual Media filters along with the other granular media is a better technology than those existing. The four main stages are the mixing, flocculation, sedimentation and Filtration. The dual media is very efficient at removing suspended solids and turbidity from the water where Anthracite removes the larger suspended solids in the initial stage of filtration and sand traps and adsorbs the fine solids and some pathogens/ microorganisms. It is important to note that the sequence of sand is maintained. The fine sand provides maximum suspended matter removal and at the same time it shouldn’t be too small so that it rises above the anthracite and remains there when the filter is in use. Siphon filter is based on the natural phenomenon of gravity to strain water to make it fit for drinking and domestic use.by making it free from any harmful micro-organisms. No use of any external energy input or any form of chemical additives used in the whole procedure. The siphon by applying a negative pressure in the filter bed lateral piping doubles the output of existing filter beds. Filtered water is delivered via conduit and the flow is controlled through valves. The S-shaped or bell siphon provides lower head room requirements, less frequent back washing and lower backwash water volume along with lower filter down time.

1. No new Filters have to be constructed. Retro fit of existing filter will DOUBLE the output of existing filter beds.

2. The system design is simple for controlling the water level through valves. Other operational controls like the backwashing, rinsing and production also involve easily operated existing backwash techniques with minimum number of required valves in overall procedure.

3. The novel siphon piping and control system prevents filter media from being disturbed and exposed to the surface during the process.

4. Extends the filter operating cycle in between the filter backwashing as well as reduces the head requirement.

5. It reduces the footprint requirement and also permits the use of same or different filter in each stage.

6. Reduces the cost of installing the system with less equipment tools requirement.

7. Provides independent and simultaneous backwashing and rinsing and hence decreases the time requirement.

Enough height of the filter should be available to easily accommodate Dual Media Filter and Siphon arrangement.

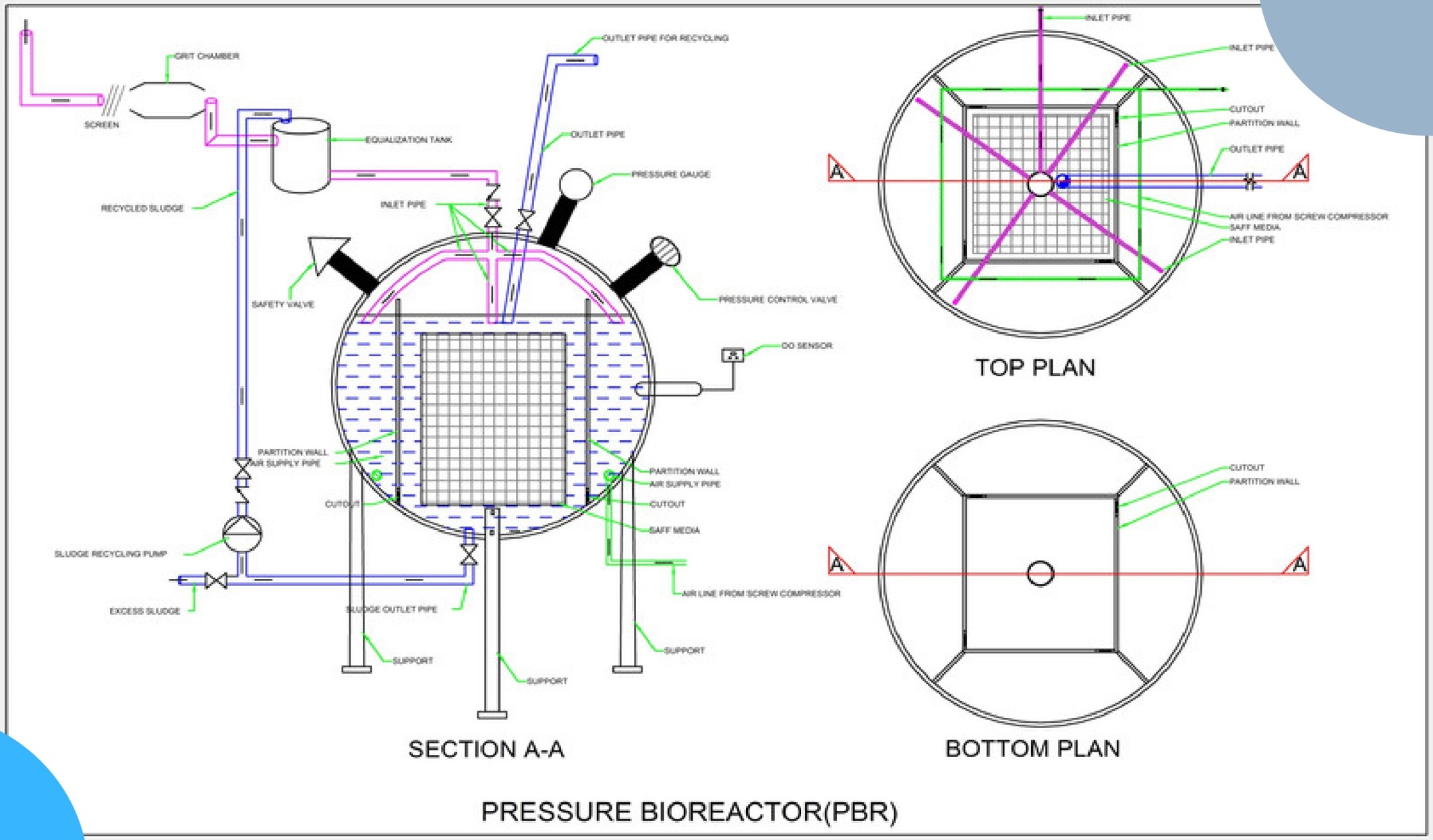

1. Small footprint of plant as, Primary Settlement, Aeration and Secondary settlement is achieved in the Reactor.

2. Has a short treatment time span for reduction of BOD / COD as Dissolved Oxygen value for the Pressurized Reactor is expected to be up to 4-6times the normal level. This high Dissolved Oxygen value is expected to increase MLSS to at least 12000mg/l to 15000 mg. per litre and speedup the reduction of B O D in the waste water significantly. The decreased reaction time will result in treatment of more batches of waste water in the Bioreactor in a day . So will also the size of the Reactor become compact

1. It is expected that the Power consumption is proportionately less while using a screw compressor instead of air blower for each mg./l of Dissolved Oxygen in the Process. A screw compressor saves 25% in energy costs. The Problem of obnoxious odor is almost absent as Reaction gasses from the Reactor will be released at a safe height from a Vent Pipe located on top of the Reactor.

2. The unit can be located near small habitations, multi-story complexes, colonies, village lands and institutions with the benefit of reduced sewage piping while taking off the load of trunk sewers in cities and towns.

3. All the Advantages of Decentralization accrue with the process. The effluent after Tertiary treatment can be used for Irrigation & Horticulture. We propose to use Solar Energy to run the reactor. The sewage generation is majorly in the morning hours when sun shine is available.